GM A/C Compressor Clutch & Pulley Bearing Saga

Updated October 11, 2011

This is not a simple job for inexperienced mechanics. It involves special tools to do correctly. I found that most all shops wanted to replace the whole compressor and all the associated parts for a considerable amount of money. There are 2 reasons they do this. First, they know that in most cases if the bearing and clutch are worn the rest of the compressor is probably near the end of it's life. If they replace the clutch and bearing and the rest of the system fails shortly thereafter no matter what they say they will have an angry customer. Repairing the multitude of compressors requires a substantial investment in special tools and specific expertise that is only practical if you are a specialty parts rebuilder.

Here's what one of my readers found. After taking the clutch off one of my friends told me to check the main bearing in the compressor by moving the shaft up and down. The bearing in my compressor was worn out. Even if I would have been successful in installing the clutch the compressor would have failed shortly thereafter.

In my case I've owned my truck from the beginning, I live north of Chicago and don't use the A/C very much at all. If it's on 10 days a year that would be a lot. I felt that there probably wasn't much wear on the compressor so I decided to replace the bearing. If you live in Phoenix you will be running the A/C a whole lot more than I. If you bought your truck used you really won't know the history.

This whole episode started last summer when the air coming out of my blower vents wouldn't change from the top to the bottom. This was traced to a failed vacuum pump. After we installed the new vacuum pump (10/02) I began to hear a high pitched whirring sound. It sounded exactly like turbo whine. We checked everything related to the turbo and couldn't find any leaks or problems. The turbo was working fine making enough pressure.

This whole episode started last summer when the air coming out of my blower vents wouldn't change from the top to the bottom. This was traced to a failed vacuum pump. After we installed the new vacuum pump (10/02) I began to hear a high pitched whirring sound. It sounded exactly like turbo whine. We checked everything related to the turbo and couldn't find any leaks or problems. The turbo was working fine making enough pressure.

I was out in Colorado in September of 04 and I heard a new louder noise. A tech at the Hummer dealer in Denver said there were 2 problems. One was the power steering pump because whenever I turned the wheel the pitch of the louder sound changed. Secondly, he said that the bearings in the turbo were getting worse and I should look into getting a new turbo. I took a chance and drove back to IL with no problems except the noise under the hood.

As soon as I got back I took some time and really got into the problem. I listened to the noise and determined it wasn't the power steering pump. Some of the accessories hanging on the front of the engine use bushings and others use roller bearings. Bushings and Bearings make different noises. A bad bushing will 'scream' or 'screech' while a bearing will make a 'whirring' or grinding sound. The noise was definitely a bearing sound. I listened to the noise with a mechanics stethoscope and determined that the noise was either coming from the air conditioning compressor pulley bearing or the belt tensioner. I pulled the belt off and gave each a spin. The A/C compressor pulley wobbled and made noise when I spun it. This bearing is a sealed roller bearing.

I was fortunate that I'd found the problem before it led to a major disaster. I knew if I continued to drive the truck with the bad bearing it would eventually sieze and cause the serpintine belt to break leaving me stranded and probably ruining the air conditioner compressor.

The second part of the saga was my quest for finding the part at the right price. Checking in my Hummer service and parts manual they showed how to replace the bearing and the pulley. The shop manual showed that you needed special tools to pull and reinstall the pulley and a special tool to install the bearing into the pulley.

The top left shows the rear of the pulley. The picture on the right shows the front of the pulley which has a friction surface for the clutch. The roller bearing is in the center.

AMG sells the bearing for 30 or 40 bucks and the bearing /pulley combination was 250.00. I have a price of around 200.00 for a complete rebuilt A/C compressor in my parts cross reference so I knew I had to be able to get a pulley for way less. I figured that these parts had to be generic because the compressor is a Delphi / GM unit. I got all the numbers off of the A/C compressor and no local parts place could find it listed anywhere.

My Compressor Information:

Delphi 6581 SAE J639 Part Number 1136581 Code 021380836

Price and availability update 2011 (the Florida place is out of business):

For the ACDelco A/C compressor P/N 1136521, the clutch, pulley/bearing parts are:

Clutch: P/N is 15-40048 Cost: $62.10 (Autopartstomorrow.com)

Pulley: P/N is 15-20038 Cost: $111.85 but doesn’t include the bearing (from autopartstomorrow.com)

Pulley/bearing assembly: P/N is 15-4615 Cost $117.77 (autopartstomorrow.com)

It was also futile to see if anything was listed under Hummer. I didn't try another GM dealer. I called a Hummer dealer and they said that they never just replace the bearing. They always replace the bearing and pulley as a unit. He said that the compressor was a GM DA6 and I could probably get the parts for way less.

After screwing around with this for a week I called the rebuilder guys in Florida. They asked me a few questions about the compressor and sold me a pulley/ bearing/clutch for 49.00. The part arrived the following week. I noticed that the front part of the assembly, the clutch plate was different then the one on my truck. After worrying about it I found out that some clutches are solid (right) and some are a flex plate (left) design and are interchangeable. The new one was a flex plate type.

Little did I know that I was in for more problems. I called one of my friends who works at a local Hummer dealer to see if I could borrow the special tool. He said he didn't have the puller set. I searched the internet and found that I could get a puller/ installer for around 25 bucks. Complete kits with all the pullers and tools ran from 60 to 300 depending on the quality. Just do a search using "A/C Compressor Clutch Tool Kit". You want tools for a DA6 compressor. I was going to order them but I knew that I'd probably use them once and I didn't want to wait anymore.

I thought I'd be able to find a shop that could just throw the pulley on for me and I'd be done. I stopped at a few independent places and each one said that they didn't have the special tools. They told me that they never do this anymore. They said that they replace the whole compressor because they found that in many cases once they replaced the front bearing the compressor went soon after, making for very unhappy customers.

I live in Northern Il and don't really use my A/C very much. I knew my compressor didn't have much running time on it and shouldn't be going bad anytime soon. I also knew that I wasn't going to buy a compressor, a filter drier and pay someone to evacuate the gas and install the new compressor because one bearing went bad. On the way home I stopped at a Carquest. Their catalog showed a puller and installer tool for a DA6 compressor for around 35 bucks (No. 200323) but it had to be ordered.

I didn't want to wait so I made one more call to a mechanic I know and got lucky. I met up with him after work and he installed the pulley for 50.00. My guess is that a Hummer dealer would have charged me 250 for the part and 120 for an hour of labor for a total of 370.00. If I had the whole compressor replaced It would have cost at least 1,000.00.

How you do it

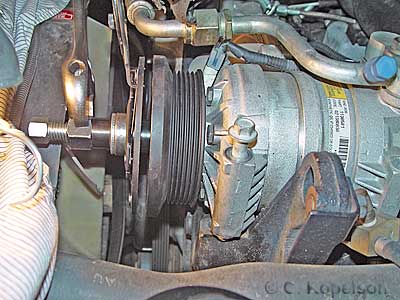

Remove the serpentine belt and unbolt the compressor from it's mounts and tilt it up so you can get to the front easier.

Remove the serpentine belt and unbolt the compressor from it's mounts and tilt it up so you can get to the front easier.

Use the clutch removal tool to pull off the clutch.

Remove the large snap ring in front of the pulley.

Remove the large snap ring in front of the pulley.

Spray some WD40 in the hub area and remove the pulley from the compressor. It's best to use the universal puller.

Spray some WD40 in the hub area and remove the pulley from the compressor. It's best to use the universal puller.

If you don't have the puller or forgot to bring it like we did bolt the compressor back down to it's mount and carefully pry the pulley away from the compressor. Be careful and don't stress the gas lines. The pulley bearing is pressed onto the aluminum casting of the compressor body so you are not prying against the compressor shaft. The bearing can be hard to remove because the steel bearing in contact with the aluminum frame will cause a dissimilar metal weld.

Clean off all the surfaces and threads using a wire brush and / or some sand paper.

Clean off all the surfaces and threads using a wire brush and / or some sand paper.

Note: The white circular object is the magnetic coil that activates the A/C.

Place the new hub on the frame and tap into place with a piece of wood or use the special puller tool which will also press the new hub into the frame.

Place the new hub on the frame and tap into place with a piece of wood or use the special puller tool which will also press the new hub into the frame.

Press the hub in until the groove is exposed enough to install the large snap ring.

Install the large snap ring. Make sure it is seated all the way around.

Install the large snap ring. Make sure it is seated all the way around.

Install the clutch assembly taking care to position the shaft key in the compressor slot. Use the special installer tool to press the clutch into place. Leave between .020 and .030 air gap between the hub and the clutch.

Install the clutch assembly taking care to position the shaft key in the compressor slot. Use the special installer tool to press the clutch into place. Leave between .020 and .030 air gap between the hub and the clutch.

Installing a new Coil (clutch core)

One of my readers informed me that some of the clutch replacement kits come with the coil. The coil is a circular electro magnet that pulls the clutch in and activates the compresser. While trying to get the coil off I removed a snap ring inside the hub which was holding the seal causing all the gas in the system to blow out; so be careful.

Mark the electrical terminal location of the coil. There is a special puller/ installer tool for removing the coil. If you don't have the puller try the following but you are on your own as far as damaging the compressor or seals.

The coil can be removed by working a couple of screw drivers behind the coil against the compressor frame. Be very careful and don’t try and force it. Be extra careful putting the new one on, it has a seal with a brass ring that needs to be pushed on. If you hit it with a socket you might nick it and the seal will probably fail.

Below is a complete set of A/C service tools.

- 99-1023 Universal Puller Arbor

- 99-457 Universal Puller Body and Thumbscrews

- 22-102 Remover and Installer Nut

- 22-101 Master Arbor

- 22-291 Clutch Pulley and Coil Removal Jaws

- 22-182 "O" Ring Installing Guide

- 22-181 Shaft Seal Remover

- 22-104 9mm Installer Adaptor

- 22-109 Removal Adaptor

- 22-292 Coil Installer

- 22-183 Shaft Seal Protector

- 99-346 Shaft Protector Pilot

- 22-381 Universal Compressor Holding Feature

- 66-187 Thumbscrews (2)

- 66-161 Long Thumbscrews (2)

- 66-156 Wing Nut (2)

- 66-152 Washers (2)

- 66-177 Washers (2)

Notes:

I found a rebuilt compressor, orifice and accumulator at a small parts house in Batesville, Total price 220 (core return 40). I found another local guy with a vacuum pump and gauges, he said put it together and he would fill it up. I talk to a few guys that have work with AC units and they told me that I didn’t need to replace the line set, evaporator and condenser as long as the system was working 1/2 or better and nothing blew up. If you try this don’t forget the o-ring gasket kit and some flush for the system. The Clutch from NAPA #261295 lists for 299.67 and they can sell it for 195.91. What a markup when you go somewhere else to have it done. Another thing the clutch puller / installer #78-3213 works really good. It lists for 38.46 and they sell it for 26.99. I was told to make the air gap between the clutch and the pulley assembly between 20-30 thousands. A big note, when you get the clutch off put the tool back on and try and move the shaft up and down and sideways. If it moves around the bearings and seal are probably bad and no need to just replace the clutch.