Transfer Case Oil Cooler

Another Cooler Design Article

Transfer Case Vampire

Broken Transfer Case Article

Updated April 19, 2016

Charles Piper's setup:

I have made several trips from Iowa to Alaska, and the Northwest Territories. This is over l3,000 miles round trip. At times, we are as much as 500 miles to the nearest services. The only tow truck is a helicopter at $l000.00 per hour, plus crew and fuel. I modified my Hummer in many ways for dependability and durability. I change my oil at l0,000 to 15,000 mile intervals. I change the transmission, t-case and other fluids at 50,000 mile intervals. I would only recommend modifying the t-case to meet special needs.

Another reason to keep the transfer case temp down is to preserve the plastic / nylon shifter parts in the case. If your case starts to shift hard the plastic pieces may be disintegrating.

In over three years and nearly l00k miles, the temperature of my t-case has never gone over l70 degrees. The only changes I made from my original is the addition of a temperature sensing switch, pump on at l70 degrees, off at l50 degrees. At present I have the pump connected to run with the ignition on. Also, I changed from a fuel pump to a Tilton oil pump. The fuel pumps are designed for extremely low viscosity fluids and can take several minutes to prime. The Tilton never runs more than 10% of the time even at over 100 degrees ambient and 60 mph. I have mounted the Tilton pump in the engine compartment where the reel light was mounted. This is a much cleaner environment, and takes less than 5 seconds to prime. No check valves, nothing fancy, just the basics. Fluid level 1/4 inch high when pump is off and 1/4 inch low when pump is on.

The Tilton pump is a Differential oil cooler pump #TIL 40-524 Buna or 525 Viton diaphragm. The main difference is the 524 has a built in 50psi bypass and improved valves, should make it better than the 522. The buna is good for 300F. My tcase stays 170 to 180 max. I can see no need for the 525.

DO NOT use the lower or drain plug as a point of pickup. This is the area that

the internal

pump uses and will cause air entrapment in ATF to both systems.

The best system is to remove the internal cooling coil and use the two openings

for your external cooling system.

I know this system works, I have used it for over 200K miles.ATF temp 150-175F

I change ATF at 100K intervals. The only thing replaced in the tcase was the

chain due to stretch.

The actual temps quoted by tilton are 265 degrees. The pump however is made by Flow Jet, Tilton only modified the housing. The polypropylene housing is rated at 130 degrees and uses elastomers of Santoprene and Buna. The Nylon are rated at about 160 max. The guy at flow Jet didn't think it was a good idea to go 100 degrees over their rated temp max. It was confirmed by him that this pump is a diaphragm --+ displacement, puller type pump. It actually presents a pulsatile flow by the bouncing of the 2 piston heads as they wobble in the valve body. Some have mentioned again that the pump can really be placed anywhere in the circuit; preferably after the cooler-to keep it coolest. The Tilton guy stressed that 1/2 hose should be used to maximize the gpm. With 3/8 hose the flow is probably less than 1-2 gpm, maybe less than 1 gpm.

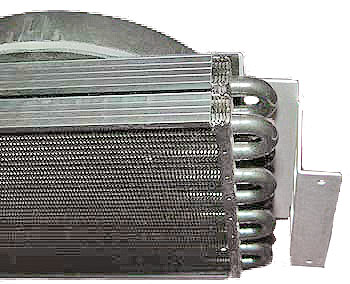

You need a considerable amount of cooling. I started with a stacked plate type cooling coil, much better than tube and fin. After many thousands of miles, it is still working fine. You need a minimum of 20,000 btu heat rejection. I mounted the pump and filter to the frame just aft of the steering gear. The cooling coil is mounted on the top, front left corner of the cooling stack.

Filter and Bracket - Summit racing equipment. #Sum G4980 (30.00).

Filter is a fram PH 8A or equivalent.

Cooling Coil - Summit #BMM-70268 (Perma Kool - Maxi-Kool XL #2430l2). Plate type heat rejection 2l,800 BTU, size l2 x 11 x 3/4 . This is the same design that GM uses for oil coolers on their trucks and vans.

I believe in keeping things as simple and dependable as possible. My system consists of Tilton Pump, filter, cooling coil, and about l5 ft. of Parker 250 psi Pushlok Hose. No clamps needed with this hose. I control the pump with a Amperite l2D l60F TSW thermal switch, and a 20 amp relay.

The pump primes within 5 seconds and never runs for more than 2 minutes. Even under the most adverse conditions, it runs less than 8 % duty cycle. The sensor for the temperature gauge is mounted in the back of the case in the area between the two chain sprockets. I drilled and tapped 1/8 FPT. The temperature has never gone over 170 degrees. Long distance interstate conditions, the temperature stays between l55 and l60 degrees. At speeds under 50 MPH the pump never comes on and the temp stays under 150 degrees..

As I said before, this is not theory, dreaming, or imagination. This is a system that has proven itself to work and be dependable. The t-case cooling is not a critical system. If it fails, the most you may have to do is clamp off the hoses and refill the t-case. Remember it is not going to cause a nuclear melt down.

I have tested many of the ideas discussed on the list for pumping the ATF. For dependability, I found the Tilton Pump, mounted high in the engine compartment to be trouble free. This pump is rated at l-2 gallon per minute flow, and can withstand continuous temperature of 265F with intermittent temperatures of 300F. My t-case fluid never goes over l70 degrees, and this pump runs less than l0% of the time, under the most adverse conditions. I tried using fuel pumps and found they did not have the required flow.

I know my system is trouble free and requires no maintenance. I have over l00 thousand miles on my present t-case cooling system.

I use, Royal Purple ATF from Humble, TX. They have many synthetic products for industrial use. I do not recommend that anyone use products other than those recommended in your owners manual. The lubricant I am using in place of ATF exceeds all specifications of Dexron and is a slightly lower viscosity. It is formulated for lubricating and cooling of large screw type compressors.

Engine oil Filter - Charles Piper

I have over 250K miles on my 94 and have used Fram filters from day one. I change oil and filters at 10K mile intervals. I use a Fram 3555 full depth, one micron, bypass filter and a PH5 standard filter with synthetic oil.

Another Method

I drilled and tapped both the drain and fill plugs for the tcase. I will warn you that this is a rather difficult job without the proper tools since the plugs are case hardened and are VERY tough to drill. If you don't have a friend with a lathe (or at lease a drill press) then buy a pair of aftermarket plugs from the auto supply store, they are usually just mild steel. After drilling the plugs, tap them for 3/8 pipe thread and install a pair of 3/8 nipples. Your lower plug will lead to an aftermarket fuel pump. I use a carter fuel pump from summit for this. It seems to work just fine, and has held up for about 6 months without any problems. There recently has been a few companies who make high heat pumps, but they are much more costly.

Between my tcase and fuel pump I have installed a remote filter, which uses a simply spin on oil filter. This allows me to filter the fluid to a couple of microns, which is a vast improvement compared to the factory setup. Underhood I mounted a Perma cool oil cooler. It is about 5 inches wide and as long as the factory radiator. Summit markets them as Transmission coolers. I have this mounted at the bottom of the cooling stack just above the power steering cooler.

The inlet of the cooler is fed from the pump, the outlet side of the cooler run back to the fill plug of the tcase. Be sure to use automatic transmission hose for everything, NOT the cheaper fuel hose. Transmission hose is rated for the higher temps that your tcase runs at. I used 3/8 hose throughout as well as 3/8 brass fittings. I have a thermocouple installed inline which allows you to monitor the fluid temp in the system. I also suggest you install an on/off switch for the pump. It is not usually necessary to run the pump while at slow speeds or at initial start up, ie it takes about 10 minutes at 60 MPH before the tcase fluid is up to 130 degrees or so.

Another Transfercase Cooler Design

First a bit of history: Prior to the installation of the cooler, my tcase (at 70 mph) operated in the 250 range. This was running synthetic Dexron. Prior to the synthetic, the tcase was operating at 280 plus (at 70 mph).

Pulling a trailer compounded the problem. I was unable to operate the truck over 65 mph without exceeding 300 degrees (16 ft boat trailer).

After installation of the cooler, the tcase operates at <200 pulling a trailer at 70 mph (uphill, both ways <smile> ). Below is a parts list for the cooler.

Precision Power 800.432.7269

Flow jet pump (CP 643-210) ~$170

Summit Racing 800.230.3030:

Transmission filter (BMM80277) $26

Oil Thermostat (PRM1060) $34

Radiator (PRM1004) $39

Fan (optional) (PRM19115) $89

Fan thermostat, etc. (PRM19001) $19

(PRM19002) $8

(SUMG4990) $7

Other:

3/8 check valve

tcase fittings

Regarding the tcase fittings: We were pretty anal about how we plumbed to the tcase. First, we wanted to be able to retain the existing drain plugs and drain plug function. Second, we wanted to minimize fittings. We finally decided to have the fittings made

by a machinist. Two fittings are required per tcase. Each fitting screws into the existing drain/fill hole, and has threads on the other end for the drain/fill plug. On the side of the fitting is a 3/8 fitting for the pump connection. The lower plug also has a 1/4 npt for a temp sender. The fittings extend about 2" from the back of the tcase, and are machined from aluminum.

I used -6 AN fittings for everything. If you would prefer barb connectors, you should get a different radiator.

The pump is manufactured expressly for pumping hot Dexron or Gear oil. It was originally part of a manual transmission cooler for large trucks. Its 2.1 gpm at 20 psi (7 amps)

The plumbing order is (easier than a pic):

1) Bottom of tcase

2) Pump

3) Check valve

4) Filter

5) Oil thermostat

6) Radiator

7) Oil thermostat (again, it has four connectors)

8) Top of tcase.

The oil thermostat helps insure that the tcase operates at nominal temps. It will reduce the fluid flow to the radiator at temps below 180. This way, the pump can run full time, without an electric thermostat.

The check valve is important to insure the tcase has the proper fluid levels at all times. It prevents fluid from draining back into the tcase if the pump is off. Also, the top tcase hose should have a significant downward angle to prevent drainage from the top. This really is a problem. If the system drains, it can take several minutes to re-prime and clear all air. (See filling below)

I attached my radiator on the top front edge of the cooling stack. Seems to work OK there. The pump is connected to the fuel pump circuit.

Filling the tcase once installed. Complete all plumbing, put the lower drain plug in, remove the upper one (just like normal):

1) Fill the tcase how you would usually do it.

2) Put the upper plug back in.

3) Start the pump. You will hear it as it clears the air from the system (the rpm's of the pump change). It took around 4 minutes for mime to clear completely. Remove the upper plug and refill.

4) Replace the upper plug.

For a street car, full-time use really makes no sense. Most of the time, the fluid is well within acceptable temperatures. So it seemed smarter to have it switched. While a manual switch is simpler, given the temps I was seeing in normal use, and my tendency to space out under the influence of speed-induced adrenaline, I wanted a thermostatic switch.

The Tilton diff pump (part # 17-522 new number is 40-524 or 525, also apparently sold under the Mocal name) is the only game in town. It is used by all the race teams. It features 1-2 GPM flow rate, is self-priming, has an integral cooling fan, and weighs 3.5 lbs. The Tilton pumps sells discount for about $175. Click here for dimensions.

The Tilton diff pump (part # 17-522 new number is 40-524 or 525, also apparently sold under the Mocal name) is the only game in town. It is used by all the race teams. It features 1-2 GPM flow rate, is self-priming, has an integral cooling fan, and weighs 3.5 lbs. The Tilton pumps sells discount for about $175. Click here for dimensions.

I chose a self-contained cooler /fan assembly, the

Derale Electra-Cool (model #15800, $130 at Summit Racing). Having a built-in fan means that it can be mounted anywhere. And the 8-AN fittings save money and allow for two less connections (it is also available in 6-AN and hose barb versions).

I chose a self-contained cooler /fan assembly, the

Derale Electra-Cool (model #15800, $130 at Summit Racing). Having a built-in fan means that it can be mounted anywhere. And the 8-AN fittings save money and allow for two less connections (it is also available in 6-AN and hose barb versions).

Another option is the Derale Electra-Cool (model #13800, $130 at Summit Racing). Having a built-in fan and means that it can be mounted anywhere. And the 8-AN fittings save money and allow for two less connections (it is also available in 6-AN and hose barb versions).

Another option is the Derale Electra-Cool (model #13800, $130 at Summit Racing). Having a built-in fan and means that it can be mounted anywhere. And the 8-AN fittings save money and allow for two less connections (it is also available in 6-AN and hose barb versions).

DER 15800 139.00

The final -- and, from a cost perspective, the most significant -- decision to be made is whether to go with stainless braided AN lines or rubber hose. Although I have used rubber hose for the oil and transmission coolers, I decided to use -AN hose for the diff cooler. The hose will be subjected to lots of movement and vibration, and is exposed to the elements -- as well as being visually exposed. You can't beat -AN stuff for the racing bling factor.

So I searched eBay and got a great deal on some 8-AN stuff ($99 for everything shown plus another 13' of hose in the box). The fittings are Russell's Endura (silver) finish, rather than the more common red/blue Earl's. To my eye, while traditional, the red/blue fittings have always looked stupid. Plus, a hack like me is bound to scratch off the anodizing during the assembly process.

So I searched eBay and got a great deal on some 8-AN stuff ($99 for everything shown plus another 13' of hose in the box). The fittings are Russell's Endura (silver) finish, rather than the more common red/blue Earl's. To my eye, while traditional, the red/blue fittings have always looked stupid. Plus, a hack like me is bound to scratch off the anodizing during the assembly process.

Many use 10-AN hose on diff coolers, but that seemed like overkill to me. Additionally, the whole system will drain back into the diff when it shuts off, so it makes sense to minimize the fluid volume in the lines. For a concise summary of AN sizes and threads, click here.

Using -AN hose, the whole shebang costs about $500-600-- $175 for the pump, $50-150 for the cooler, and $150-200 for the AN stuff. But you can shave off over $100 by going with rubber hose. If you want a thermostatic switch, add another $25-40. If this seems steep, you can take consolation in knowing that many more-money-than-sense Porsche, Viper, and 'Vette guys pay $1,000 - $1,800 for essentially the same setup.

Many use 10-AN hose on diff coolers, but that seemed like overkill to me. Additionally, the whole system will drain back into the diff when it shuts off, so it makes sense to minimize the fluid volume in the lines.

Using -AN hose, the whole shebang costs about $500-600-- $175 for the pump, $50-150 for the cooler, and $150-200 for the AN stuff. But you can shave off over $100 by going with rubber hose. If you want a thermostatic switch, add another $25-40. If this seems steep, you can take consolation in knowing that many more-money-than-sense Porsche, Viper, and 'Vette guys pay $1,000 - $1,800 for essentially the same setup.

Dave Breggin's Comments:

When I was first testing aux. cooling for the t-case, I used this method:

I simply looped the transmission lines back and attached a pump and

radiator to the existing cooling loop.

Later, I removed the cooling loop and put lines in those holes so that it would actually circulate the fluid in the t-case. I also added a spin-on filter to the circuit.

Results using the existing cooling loop were satisfactory. Moving the actual fluid (not to mention being able to filter it) does work a bit better.

I got a thermostatic switch designed for aux. cooling fans and hooked it up to the pump. I put the sensor on the t-case. If you put the sensor on the line, the pump will never come on since fluid will not be passing through the line because the pump is not on.

I have never felt the need for cooling fans with this setup.

Argument for leaving the cooling loop intact:

I left the existing loop intact, so that each is separate. My fear was that off-roading could break a line, and I didn't want to loose the tcase's fluid.

I really think the issues with maintaining the proper level in the tcase when you try to directly cool it can be a major problem. You have to account for the fluid in the cooling system then, and deal with the issue of drain back effectively overfilling the tcase and possibly leaking.

I didn't worry about a filter on the cooling loop since it should not ever mix with the tcase's fluid. Were I to plumb directly and cool that way I'd recommend a filter.

BTW, my setup took only an hour or so to install, remove the existing cooling lines, hook up new ones and run them to the front (easy, really) drop in a pump and the cooling coil. The most difficult thing was removing the inner fender to route the hoses to the front of the radiator stack.