Gasoline Powered Hummers Tech Page

Updated January 30, 2023

AM General produced the Gas trucks in 1995 and 1996. All the diesels prior to 1996 are NA (naturally aspirated) diesels as opposed to turbo diesels which were introduced in 1996. The drive train on the 95 and newer trucks is all the same except for 1998 when they changed the differential ratio. My first truck was a gas truck. The second Hummer I had was a 96 Turbo Diesel wagon. My present truck is a 1998 Turbo Diesel wagon.

The 5.7L (350 cu. in.) TBI gas engine installed by AMG is the 1995 GM LO5 version, further identified as GM Assembly no. 10205700 ..with a 3 page list of AMG add/delete components to facilitate installation in the HUMMER (H1). Basically the engine falls into GM's Medium Duty Truck/Van gasoline engine classification. Also when the first gas engine was installed in 1995 model year HUMMERs, the T-case had to be beefed up to withstand the spike input torque the gas engine was able to generate above those of the HUMMER 6.2L and 6.5L N/A diesel engines of that day.

The OBD connection for a gas truck is really an OBDI with an OBD2 connector. The OBDI DLC, data link connector looks like an OBDII DLC so it requires an adapter (GM 16/12 pin Non-OBDII DLC, P/N 02001575) made by Vetronix, sold to SPX that fits on the end of an OBD1 cable of a Tech 1A or Mastertech reader. Now that is a mouth full. I just gave you 6 months experience in getting the correct setup in one sentence.

In my opinion there isn't much difference between the off road performance of a gas vs. a non-turbo or NA diesel truck. Remember, in 1995 the choice was between NA diesel and gas. After I bought the gas truck I went to the AMG test track and had the opportunity to drive one of their diesel trucks through all of their obstacles. What I found is that each engine has it's own distinct feel. I took my gas truck to Colorado and Moab Utah twice and had no problem going anywhere I wanted. Another benefit of a gas truck is that it will allow much more compression engine braking due to a difference in the nature of a diesel engine's air intake vs. a gas engine, but that's another story.

Why did I get a gas truck? Because I felt that I could get fuel anywhere. If I'm out on the trail and somehow run out of gas the probability of a diesel truck coming along is very remote. The 350 Chevy small block is the most common engine ever built and can be repaired almost anywhere in the country. If the engine doesn't last as long as a diesel it can be replaced dirt cheap. There are more add on parts made for this engine than any other engine in existence. Its quieter and starts up with no problem in the coldest weather. The gas truck can be sound insulated very easily. The fuel injection system automatically adjusts itself for the correct mixture at any altitude. The NA diesel has a tendency to smoke at high altitudes. Don't forget, just about all other 4wd's made are gas powered.

The negatives about a gas truck are: You can't ford to a 30" depth. The starter on a gas truck is not watertight and will only allow a 24" ford. The 95's have 23 gal gas tanks which are small considering that you will get 8 to 11 mpg. I researched adding the newer 17 gallon tank to the 95. It required moving the exhaust, changing the trailer hitch, cutting the body for the second fuel filler and adding all the electrics to handle 2 tanks. There were 100's of parts and it cost a fortune. I ended up just carrying a 5 gallon jerry can. Off the road while in Colorado I got about 4 mpg. All the 96 trucks (gas & diesel) have an additional 17 gallon tank. You have a high voltage electrical system that can get wet. The gas engine will produce its power at higher RPM's so it's necessary to put your foot down a little more when going over obstacles.

When I had my 95 gas wagon I examined ways to increase the performance of the engine. The objective was torque at low Rpm's. Most modifications to gas engines increase the horse power at high Rpm's. The solution to the problem was to install a Whipple supercharger. A supercharger would allow me to keep the truck stock and increase the horsepower from 180 to almost 300 and do it a low Rpm's. The kit consists of a new intake manifold, the supercharger, K&N air filter assembly, pulley, and programming chip. It will require you to use premium fuel. The unit costs around $5000 and will cost $1,800 to install, unless you do it yourself. The 350 block used in the Hummer is a heavy truck/marine unit with 4 bolt mains. It will take the added stress with no problem. I drove a Whipple charged truck and clocked it 0 to 60 in 13.5 seconds. It drives around town and moves in and out of traffic like a nimble Jeep. The owner has had it installed for 2 years now with no problems. Unfortunately the Whipple is no longer available for the Hummer. I'm sure that there are other super chargers that would work. Others have just installed 'built' engines or converted to big block V8's.

Read more in my Gas vs Diesel Article.

Note: Most problems with hard starting and stalling are fuel system related. The fuel pump in a gas truck is in the gas tank.

Fuel Tank

The gas truck tanks hold 23 gallons because the fuel pump is in the tank and there is room for vapor expansion. Gas is much more volatile and expands much more then diesel fuel

There was a recall on gas trucks in 1995. The fuel venting system had a problem which caused the fuel tank to expand and come in contact with the drive shaft which would then cut a hole in the tank spilling gas all over. Many times the expanding fuel would blow through the top tank gasket spilling fuel all over whenever you filled up.

The fuel gauge sending units on all the early trucks were inaccurate. I think they had 2 or 3 revisions on these. Your fuel gauge wouldn't read full when full and never got to empty.

There was also a recall on the gas pedal bushing. The early one's caused the pedal to stick.

A quick way to tell is to look at the accelerator rod that the pedal is attached to. If it is silver, it is the replacement. If it is still black painted steel, it is the original version and needs to be replaced.

And yes, there was a safety recall (AMG R96-01) involving replacement of the

accelerator pedal rod (bellcrank) assembly. That recall included all 1995

and 1996 Gassers through VIN 170871. Your friendly local HUMMER Dealer should

be able to run your VINs for you to see if that recall has been performed.

If you cannot get them to do it, call AMG's toll free number provided in the"Warranty" section of any of your Owner's Manuals.

Fuel Pump & Relays

AC Delco EP377 or GM 25163472 pump with a AC Delco TS1 strainer. These are high volume and higher pressure fuel pumps.

I've gone through 2 F/P relays. I believe the problem was self induced. I had left the key in the "ON or RUN" position for an extended time while I worked on the H1! After that when I went to start them the F/P relay was shot. Also FWIW a replacement that I've had good luck with is "GP-Sorensen" p/n MR44...available at Advance Auto and many other such auto parts stores.

Make Sure you Have Gas

It didn't happen with my Hummer but a Jeep my daughter was borrowing died on her one afternoon. I ran out to help and was able to drive it off the main road and park it on a side street. The fuel gauge read more than 1/2 full. The next day I came out and changed the plugs, distributor cap, rotor and it still wouldn't start. I heard that that particular year Jeep had problems with the crankshaft sensor. After tracking one down I installed the new sensor. The thing still wouldn't start. I decided to pour some gas down the air intake to see if I could at least get some life out of it. Bang! it started right up. I poured the rest of the gas in the tank and the darn thing ran. Turned out to be a bad fuel gauge. Early Hummers have notoriously bad fuel gauges.

I had another problem with a jeep. I was on the highway driving out to CO one year. The truck kept stalling and dying. I stopped in IO and installed a new fuel pump. Still didn't fix the problem. I pulled over at a gas station and dropped the fuel tank and threw out all the gas. I still had the problem but it wasn't as bad. When I got to Denver I called a Jeep dealer. They said I should drop the tank and throw the gas strainer as far away as possible. As time went on the overley fine strainer was filling up with sediment from the gas tank and preventing fuel from getting to the engine.

I had a 68 Camaro where the engine would die when the tank got down to about 1/4 full. The engine had died in the parking lot next to my apartment so I decided to see if there was actually gas in the tank. I dropped a 1/4" tube down the filler neak and blew air and listened for bubbles. I didn't hear bubbles so I decided to suck. Bad Idea, I got a mouthfull of gas. Gas has a specific gravity way lower than water so it's not going to make bubble noises like water. Turned out parking my car in the empty lot was the problem. I had backed into a rock that dented the gas tank and bent the tank filler tube up so it wasn't sitting on the bottom of the tank. When the level in the tank dropped under the tube no more fuel.

Test Your Fuel Pump:

You should check both pumps (96) which are placed in both tanks. These are independent of each other. Use the selector switch. If both pumps are not putting out enough pressure you can adjust the pressure on the output line. There is a black cylindrical valve with an Allen screw.

If it does not help, then think weak pumps located in both tank(s), blocked lines, a bad switch-over valve/tank selector, clogged fuel filter etc. I have high flow pumps. At ignition and idle I have 15 PSI and when accelerating I have up to 30 PSI. (I have a Whipple supercharger that needs the high flow pumps).

Intermittent Engine Stalling:

I think I might have solved my problem of intermittent engine stalling. While checking things underneath I noticed that two hoses had slipped in the ~1/2" crack between the gas tank and the frame. One of these was a fuel line (couldn't tell if it was the supply or return line). The fuel runs in a hard line (to/from the engine) on top of the frame rail until it gets near the middle of the tank, where it is connected to a rubber hose that goes up to the top of the tank. The hose appears to have a little extra length in

So the loose rubber hose had worked its way down in the gas tank-frame rail crack. This wouldn't have been so bad, but another harder rubber hose, I guess the CTIS line because it seems to run aft of the gas tank, had worked its way into the crack too. In the crack the two hoses overlapped, and you could see that the fuel line was already pinched a little. Since heat was one ingredient for the engine stall problem I've had, I guess the gas tank had expanded enough to completely pinch the fuel line.

The same stalling behavior also occurred under some trail conditions too. Maybe in this case a small amount of flex between the body and frame rail could have caused the pinching as well.

Engine Won't Start:

The starter turns the engine over fine but it won't catch. If you smell gas around the air inlet you probably don't have to check the above items. What I do is pour a little gas down the throttle body inlet and see if it starts. If it starts I start looking for fuel problems. Otherwise it's probably electrical.

Make sure the engine compartment is dry. You can use a spray drying agent like wd-40 on the plug wires and the distriburor cap.

Pull one of the plug wires off and have a friend crank the engine while you hold the wire close to a ground. You should see a spark jump. If you don't, pull the coil wire out of the distributor and see if you get a nice fat spark to ground. If you do your problem is either the cap, rotor, wires or plugs. Even with marginal plugs the engine is going to at least cough and sputter. Open the distributor and check for dampness and the quality of all the electrical contacts on the rotor and the cap. If the electrical parts haven't been replaced for a long time now would be a good time. If you don't have a spark from the coil it could be the coil wire, coil or the computer. This is pretty rare.

Air Filters:

Baldwin PA1710 $27.00 each

O2 Sensor:

Has anybody had any experience with trying heated O2 sensors. It seems that the position of the O2 sensors on my 95 gasser is so far away from engine it doesn't have a chance to get as hot as it should and maybe a heated O2 sensor would make the truck run better?

Have no experience with a heated O2 sensor on '95 or '96 Gassers, but if you just wanted it to get it hotter quicker, you could move it back up to the originally designed location...the left exhaust manifold ...or 'wrap' the pipes back at least as far as the O2 sensor.

Gas Engine Exhaust Manifolds

The cause of manifolds on gas trucks cracking is due to the exhaust twisting the manifold. What I did after repairing mine was to loosen all the joints in the exhaust which lets all the bits move to where they want and then starting at the manifold tighten them all up. No more cracks since I did it .Sequential tightening (Rt. side/Lt. side/Rear) of the exhaust Y-pipe fastening hardware is the key to preventing cracked Gasser exhaust manifolds.

Gas Engine Exhaust Manifolds

The cause of manifolds on gas trucks cracking is due to the exhaust twisting the manifold. What I did after repairing mine was to loosen all the joints in the exhaust which lets all the bits move to where they want and then starting at the manifold tighten them all up. No more cracks since I did it .Sequential tightening (Rt. side/Lt. side/Rear) of the exhaust Y-pipe fastening hardware is the key to preventing cracked Gasser exhaust manifolds.

Large 'Donut' exhaust gaskets used in the '85-'04 6.2L, 6.5L, NA, TD, and Gas H1 or HMMWV. Check out the attached photo below (Exhaust-Gasket.bmp).

Large 'Donut' exhaust gaskets used in the '85-'04 6.2L, 6.5L, NA, TD, and Gas H1 or HMMWV. Check out the attached photo below (Exhaust-Gasket.bmp).

It shows this gasket having an alternate application of a '82-'92 VW / Audi 1.6L Diesel, 1.8L VG30 Engine with VW Part # 161298115 and 533253115B. Other part numbers shown on this picture are: AMG Part # 12338339, NAPA Part # F-7442, FelPro Part # 60576, NINN Part # 01-200-0466, and NSN Part # 5330-01-200-0466. This is the large 2.8" ID exhaust gasket that fits on the exit end of the crossover Y-Pipe, the catalytic converter, muffler, and deep water fording pipe.

Pricing and availability can be found at:

NAPA auto parts (www.napaonline.com, part # F7442): $22

Kascar (www.Real4wd.com, AMG part # 12338339, NSN 5330-01-200-0466): $5

Hummer dealer (www.hummer.com, AMG part # 12338339): $10

Volkswagen dealer (www.vw.com, part # 161298115, 533253115B): $28

1995 - 96 Air Filter for Gas powered trucks

Kascar has them for 70.00 ea 5744159 A-5025<

Engine cover goes under the "dog house" is available for $149 at www.myhumvee.com. It is AMG Part # 6003199 and lists for $478 at the Hummer dealer. This is the engine cover for a '95-'96 Gas H1, but will fit other H1 or HMMWV models. It has the factory molded in hump to clear the chevy small block distributor.

Engine cover goes under the "dog house" is available for $149 at www.myhumvee.com. It is AMG Part # 6003199 and lists for $478 at the Hummer dealer. This is the engine cover for a '95-'96 Gas H1, but will fit other H1 or HMMWV models. It has the factory molded in hump to clear the chevy small block distributor.

Gas Diagnostics

ALL Gas trucks are OBD1. Little known fact; ALL '96 HUMMER Gas engines were GM (LO5) 5.7L versions actually "built" in 1995. So when looking up engine spec 's for a '96 Gasser, just lookup '95 Medium Duty GM 5.7L LO5 engine data.

Engine Analyzers:

I ended up owning the OTC/SPX Techmate I, GM 16/12 pin NON-OBD II DLC (data link connector) adapter (#02001575) and OBD II conversion kit for my 95 Gas truck.

The OBD II kit is required for all the other trucks we work on (some 1996 and all the newer ones).

1996 was a year of change so you may have either one of these setups. In 1996, the DLC connector looks the same for both OBD types. This required a special adapter to the pre-OBD II meter. 1996 was the transitional year.

To make matters worse for you and I and other '96 Gasser Owners, you need to 'trick' the OBD software into thinking our vehicle is a 1995 Chevy Medium Duty Van or something like that..go figure!!! The 'trick' is in the VIN and Doug H. at AMG should be able to tell you which digits/letters to substitute where.

Replacing the Flexplate / Flywheel

For some reason this is a common problem on the gas trucks. When I had my 95 the flexplate was one of the earlier problems I had.

1. Remove the exhaust pipe.

2. There is probably no reason to replace the rear main seal. Replacing this seal may cause more problems than leaving it alone. (If it ain' t broke, don't fix it)

3. 5743902 - Flywheel Asm 5.7L GS. - I recommend bolts be replaced: 57439003 (you need six).

Be careful not to allow the torque converter to slide off the transmission input shaft.

Unbolt the torque converter *before* unbolting the transmission case from the engine to prevent input shaft/seals damage.

Torque of all attaching bolts is critical. Use a good torque wrench, don't guess.

After replacing the flywheel, you must realign the starter as per the manual, adjusting shims as necessary for correct clearance. Failure to do so can cause damage to the starter and/or flywheel.

Transmission/transfer case must be supported when the rear cross member is removed.

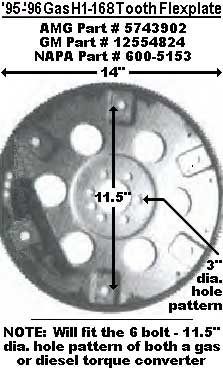

Thanks Gilbert and Peter for looking up the AMG part number (AMG part # 5743902) for the gas H1 flexplate. After ordering it from the hummer dealer, we found out there were other compatible part numbers. When the flexplate was picked up from the dealer, the GM part sticker was still on plate and was GM part # 12554824. NAPA auto parts has this item also and is NAPA part # 600-5153. This is the 168 tooth, 14" diameter heavy duty flexplate used for '86 and newer chevy small block engines with a 3" crankshaft flange bolt pattern. It fits the 6 bolt - 11.5" diameter hole pattern of both the gas and diesel H1 torque converter. Both the 4 speed 4L80E automatic transmission and the older 3 speed turbo 400 trans will work with this flexplate. Attached is a photo and the information from the GM parts catalog

Thanks Gilbert and Peter for looking up the AMG part number (AMG part # 5743902) for the gas H1 flexplate. After ordering it from the hummer dealer, we found out there were other compatible part numbers. When the flexplate was picked up from the dealer, the GM part sticker was still on plate and was GM part # 12554824. NAPA auto parts has this item also and is NAPA part # 600-5153. This is the 168 tooth, 14" diameter heavy duty flexplate used for '86 and newer chevy small block engines with a 3" crankshaft flange bolt pattern. It fits the 6 bolt - 11.5" diameter hole pattern of both the gas and diesel H1 torque converter. Both the 4 speed 4L80E automatic transmission and the older 3 speed turbo 400 trans will work with this flexplate. Attached is a photo and the information from the GM parts catalog

Supercharge your Gas Truck

I have a 350 with a Whipple installed several months ago. I found a used one on Humvee.net. It is critical to get a complete system ... this includes manifold, supercharger, AC bracket, idler arm, pulleys for the entire front end, computer chip, fuel regulator, air cleaner canister, hoses, TBI bonnet and etc. It is best to get a system removed in total, rather than trying to find individual parts. Whipple stopped making them around 5 years ago and specialty parts made by Whipple for the Hummer unit are not available.

Next, you need a mechanic that knows what they are doing. The guy I bought it from first melted a head gasket then blew the engine. It turned out that the fuel regulator was set way too low. These need new pumps in both gas tanks capable of 50 psi with the regulator set near 30 psi when engine off and around 20 psi when at idle. They require a minimum of 92 octane and get 8 mpg. I was getting 11 mpg prior to the install. Great Lake Hummer installed mine. It took around 5 weeks in total, which included a nationwide search for several critical parts.

The supercharger works full time. I have a gauge that watches the boost and when you tickle the pedal, it climbs to 6 psi. I just purchased a fuel pressure gauge, for you will blow the engine if you loose psi and run the engine lean. I also have a Jacobs controller with high voltage coil. It has sensors measuring the boost and adjusts the spark advance automatically between idle and boost. It also has an rpm limiter function.

The increase in horsepower and torque are unbelievable. I now keep up with the turbo-diesels on the difficult trails and can beat most cars off the line if I want to pay the $$$ for the experience. Short of selling my gasser and buying a totally different truck, I had no other choice to increase my power and torque but to supercharge it. The total cost with installation, used parts, some new parts (serpentine belts, fuel pumps, idler, and etc) was around $6,000.

It was money well spent, for my 1996 trade in, finance charges and the price of an 2004 would have been around $60 - 70,000 out of pocket.

I love my truck and have worked on it at least one day per week for 6 years or so, except for winter. It really is better than new. Better paint, interior, engine, drive train and accessories.

My 95 Gas H1 quits and fails to restart

I am six months into this problem myself and with one failed attempt by a local expert. I have replaced the distributor, coil, wires, plugs, oil pressure switch, coil wire - cleaned and reinstalled three engine block grounds, one steering column ground - checked fuel pump , fuel tank contamination, fuel sender.

Those symptoms sound a lot like you have a VENTED fuel filler cap installed in lieu of a correct NON-VENTED cap design!!!

Other items to check are;

Has the 'vent system recall' been performed on this '95 Gasser H1? Is the charcoal canister clogged and/or the lines running to/from it obstructed? Check the fuel pump and filter.

My 95 gasser ran roughly when it was hot, especially at idle. However, new spark plug wires fixed the problem. My mechanic told me that the insulation was weak so that some subtle shorting was occurring. Maybe extended engine heat over a long time broke the insulator down faster than normal.

Why do the gas trucks have 2 air cleaners?

There is so much air available they can't possible use it all? Wouldn't the diesel setup (480 cfm) be enough? Or, why wasn't the diesel setup considered enough?

When developing the Gasser for 1995 model year all they had to work with was the original 380 CFM rated air cleaner used on 6.2L & 6.5L N/A Diesels and that was underrated for the Gasser's application.

At the time United Air cleaner had a smaller size canister & lower CFM element design available. Twin smaller size air cleaners were chosen to make up for the shortcoming of the 1 larger size, but resulted in that "extra capacity" you were asking about.

Notes:

a.) Later for the 1996 Turbo-Diesel, United worked some magic on the old 380

CFM model and qualified it as a 420 CFM rated air cleaner ...and it has been

used on HUMMER H1's and HMMWV's since that time.

b.) Keep mind all these CFM flow ratings are NOT simply the amount of air

that can "flow" through an air cleaner, but rather the amount of air being"filtered" by the air cleaner to meet very specific requirements.

New Engine Options for a Gas Hummer

Remember, you want torque at low RPM, not super high horsepower at high rpm. This information is from 2004 so it's subject to change.

Assuming that you're sticking with the TBI system, GM sells a nice entry level crate motor 330hp/380fpt

Scoggin Dickey sells it for just at $2,400.00.

A small step up in power 355hp/405fpt step up is the venerable ZZ4 from GMPP's ZZx series motors. Current version is about 3800.00

The next step is GM's 383 stroker line ostensibly for trucks. The HT383 boast 325hp/415fpt for about 4000.00.

The zenith of GMPP's small blocks is the ZZ383/425. Combining a HT383 short block with the GMPP '846 cam and aluminum 'Fast Burn' heads for 425hp/460fpt. $4800.00 for this one.

Now all of these will require some work to make happen. With the exception of the ZZ4, the intakes bolts are all new style 'Vortech' bolt pattern using 8 3/8ths instead of 12 SAE bolts. You'd need a TBI intake with the new bolt pattern.

But the clincher here will be the tuning. TBI tuning isn't exactly HARD, generally the injector tables are pretty coarse from a programming stand point. What you'll have to do is to tune with fuel since as far as I know there's no tuning tables for the H1 gasser ECM's. So that means bigger fuel injectors (either 65pph from a TBI Caprice or 83pph from a big block truck) combined with a chassis dyno and a adjustable fuel pressure regulator.

Personally, I'd look at the HT383 or the ZZ383. Maybe with a cam swap. You'd shave off 100lbs with aluminum heads and even a GMPP 845 cam would net you 360hp/400fpt pretty easily.

Kits needed to do a full HVAC Upgrade on a 1996 GAS WAGON:

[if you can still get it]

1 pc. AMG p/n 5744965 Basic Upgrade Kit (approx. 86 individual parts)

[or if not, get]

1 pc. AMG p/n 5745605 Basic Upgrade Kit (approx. 86 individual parts)

1 pc. AMG p/n 5744797 Wagon Ventilation Kit (approx. 53 individual parts)

1 pc. AMG p/n 5744961 1996 Gas Accessory Kit (approx. 30 individual parts)

1 pc. AMG p/n 6009143 Control Head (1 part)

Kits come with detailed instructions and drill/cut templates as required.

Total of "Kit" costs should be around $2,400. or so.